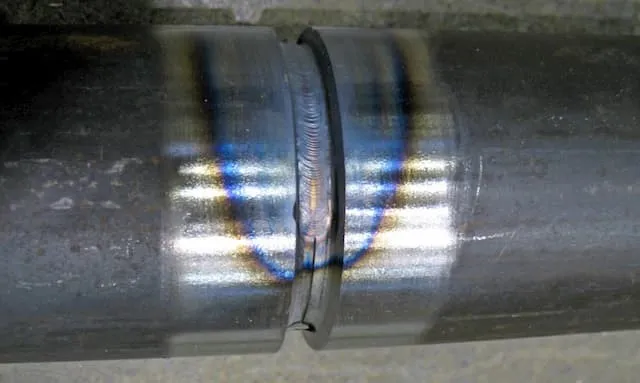

TIG welding is known for its precision and high-quality results, but it comes with its own set of complexities and challenges. According to Ron Covell, a renowned welding expert, one of the biggest hurdles in TIG welding is maintaining a steady hand and consistent arc length. This can be especially challenging for beginners who are still developing their coordination and control.

Learn practical TIG welding techniques to work faster and improve precision. This guide covers torch control, heat adjustment, and common mistakes to avoid—helping you create cleaner welds with less practice time.

Table of Contents

Toggle1.Understanding TIG Welding: Core Concepts for Beginners

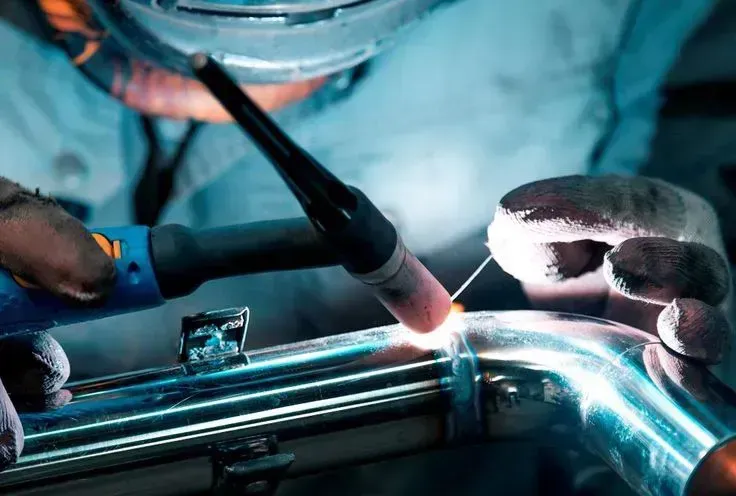

TIG welding, or Tungsten Inert Gas welding, uses a non-consumable tungsten electrode to produce the weld. It’s prized for its precision and ability to weld thin materials. Key concepts include maintaining a clean work area, as contaminants can affect weld quality, and mastering the balance of heat and filler material. Control is crucial—steady hands and consistent torch movements are essential for producing smooth, high-quality welds. Understanding these basics will set a strong foundation for developing your TIG welding skills.

CNAWELD WP26 TIG Welding Torch

CNAWELD WP26 TIG Welding Torch

2.Keeping Everything Clean: Essential Preparation Before Welding

Cleanliness(Tips For Cleaning The Metal) is crucial in TIG welding because even tiny contaminants can cause weld defects. Dust, grease, and other particles can lead to weak welds and multiple contamination issues. Different materials require specific cleaning tools and methods.

For aluminum, start by wiping it down with acetone to remove any oils. Follow this by cleaning with a stainless steel brush or non-abrasive pad to remove oxides. For stainless steel, an acetone wipe ensures no residue remains. Always clean your work area, tools, and materials thoroughly before starting. This ensures a high-quality weld and reduces the risk of defects. Proper preparation is the key to successful TIG welding.

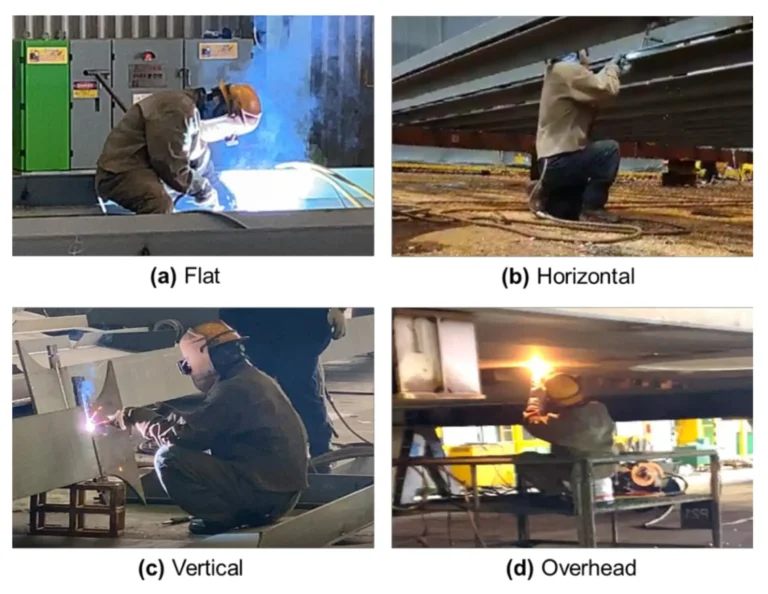

3.Selecting a Stable and Comfortable Position for TIG Welding

A stable and comfortable position is crucial for successful TIG welding. Ensure you’re seated or standing in a way that allows you to maintain steady control over the torch and filler rod. Position yourself so that your arms and hands are well-supported to reduce fatigue. Besides using external supports, your body can also provide excellent stability. Rest your arms on a table or brace them against your body for added control. Adjust your workpiece to a comfortable height and angle to avoid awkward postures. Consistency in your stance helps maintain a steady arc and improves weld quality. Always prioritize comfort and stability to achieve the best results.

4.Mastering Torch Handling: Techniques for Steady Welds

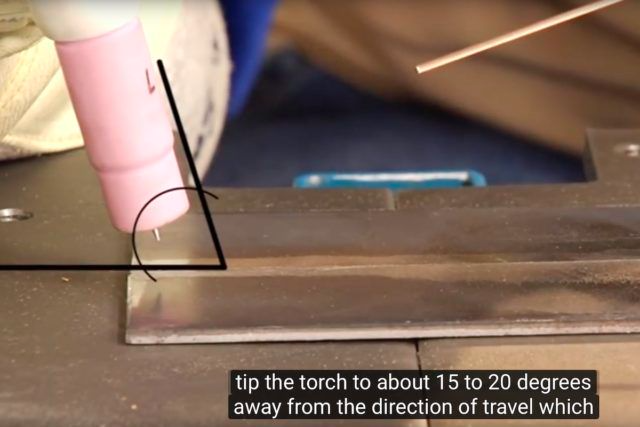

Proper torch handling is essential for achieving smooth, high-quality TIG welds. Start by ensuring a comfortable grip on the torch. Hold it like a pencil, allowing for precise movements. Keep your hand steady and close to the workpiece, which helps maintain control and reduces the chance of an unsteady arc.

Use a consistent, slow pace while moving the torch along the weld path. Avoid rapid movements, as they can cause inconsistencies in the weld bead. Practice using your wrist to make small adjustments, as this provides better control compared to moving your entire arm. Resting your hand on the workbench or using a support can help maintain steadiness.

Additionally, focus on welding angles and welding distance. The torch should be at a 15-20 degree angle from vertical and about 1/8 inch above the workpiece. This positioning ensures proper shielding gas coverage and optimal heat input. Regular practice will improve your torch handling skills, leading to cleaner and more consistent welds.

5.Proper Filler Rod Techniques: Achieving Strong, Clean Welds

Selecting the right filler rod is crucial for strong, clean TIG welds. The key factors to consider include the type of material you’re welding and its thickness. For example, aluminum requires a different filler rod than stainless steel. Ensure the filler rod matches the base metal to avoid contamination and ensure compatibility.

When welding, feed the filler rod steadily and consistently into the weld pool. Hold it at a slight angle to avoid it dipping into the weld pool directly, which can cause contamination. Proper filler rod handling and selection will significantly improve the quality and strength of your welds.

6.Heat Control in TIG Welding: Preventing Warping and Overheating

Controlling heat is vital in TIG welding to prevent warping and overheating. Too much heat can distort the workpiece, while too little can cause weak welds. Use a lower amperage setting for thin materials and increase it for thicker ones. Keep a steady pace to avoid overheating any one area.

To manage heat effectively, use techniques like backstepping, where you weld in short sections and then move back. Also, pause occasionally to let the material cool down. Proper heat control ensures strong, clean welds without damaging the workpiece.

7.Do a Practice Run: Perfecting Your Technique

Before starting your actual weld, it’s beneficial to do a practice run. This helps you get a feel for the torch angle, travel speed, and filler rod handling without committing to the weld. Use a piece of scrap material to simulate the weld. Practicing helps you refine your technique, adjust your settings, and ensure everything is correctly set up. By doing this, you can identify and correct any potential issues, leading to better and more consistent welds in your actual project.

8.Maintaining Your TIG Welding Equipment: Tips for Longevity

Proper maintenance of your TIG welding equipment ensures longevity and consistent performance. Regularly check your torch, cables, and connections for wear and tear. For instance, inspect the torch’s nozzle for any signs of damage or buildup and clean it regularly to ensure smooth gas flow. Replace worn-out parts promptly to avoid interruptions during welding.

Keep your welding machine clean and dust-free by wiping it down after each use. Store your equipment in a dry, clean area to prevent corrosion and damage. Regular maintenance not only extends the life of your tools but also guarantees better welding results.

9.Practice Makes Perfect: Developing Your TIG Welding Skills

Consistency and persistence are key to mastering TIG welding. Regular practice helps you develop muscle memory, refine your technique, and improve control over the torch and filler rod. Start with simple projects and gradually take on more complex ones as your confidence grows. Always prioritize safety by wearing appropriate protective gear and ensuring a well-ventilated workspace. Pay attention to your mistakes and learn from them. Document your progress and adjust your methods based on what you learn. By committing to continuous and safe practice, you’ll see significant improvements in your welding skills and overall quality.

With dedication and attention to detail, anyone can become proficient in TIG welding. Consistent practice, combined with the right techniques and safety precautions, will lead to significant improvements and high-quality results. Keep learning and refining your skills to become a more confident and skilled welder.