Table of Contents

ToggleWhy is an inert shielding gas required for GTA welding?

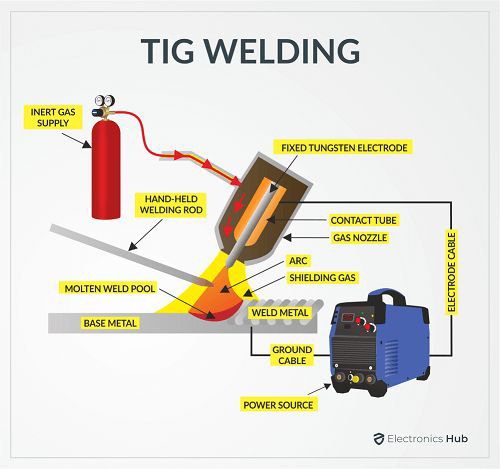

Gas Tungsten Arc (GTA) welding, also known as Tungsten Inert Gas (TIG) welding, is a popular welding process used in various industries, including automotive and fabrication. In GTA welding, an inert shielding gas is essential for achieving high-quality welds. But what exactly is the purpose of this shielding gas and why is it required? Let’s delve deeper into this topic to understand its significance.

TIG Welding Process Source:Electronics Hub

Protecting the Weld Metal

At its core, the purpose of an inert shielding gas in GTA welding is to protect the welding area from atmospheric contamination. During the welding process, a high-energy electric arc is formed between the tungsten electrode and the metal being welded. This arc generates intense heat, melting both the electrode and the base metal. If exposed to the surrounding air, the molten metal and the electrode can react with atmospheric gases, such as oxygen and nitrogen, leading to defects in the weld and compromising its strength and integrity.

To counteract this potential problem, an inert gas is used to create a protective atmosphere around the weld pool. Inert gases, such as argon and helium, are chemically unreactive, meaning they do not easily interact with other substances. When introduced into the welding environment, these gases form a stable shield that prevents the entry of atmospheric gases. This shield acts as a barrier, ensuring that the molten metal and electrode remain isolated from the air, thereby minimizing the risk of defects.

One of the main benefits of using an inert shielding gas in GTA welding is the ability to produce clean, high-quality welds. By eliminating the presence of oxygen and nitrogen, the risk of contamination-related defects, such as porosity, excessive spatter, and brittle welds, is significantly reduced. This ensures that the weld joint possesses the desired mechanical properties, including strength, ductility, and corrosion resistance. In industries where safety and reliability are paramount, such as aerospace and automotive, these qualities are crucial.

Protecting the Tungsten Electrode

The non-consumable tungsten electrode is intended to initiate and sustain the arc rather than to contribute filler material (or: rather than to be consumed) during the welding process.The tungsten will react with air when it reaches temperatures above approximately 500℃—which it does during the welding process—so a shielding gas is necessary to isolate the hot electrode from the surrounding atmosphere.

Influencing Arc Characteristics and Weld Penetration

Furthermore, the use of an inert shielding gas allows for better control over the welding process. Welders can manipulate the weld pool and electrode more effectively, resulting in precise and aesthetically pleasing welds.

The shielding gas acts as the medium for arc heat transfer, and its thermal properties can be utilized to achieve deep penetration. For example, helium’s thermal conductivity is about 10 times higher than that of argon. Such high thermal conductivity allows the heat generated by the arc to be transferred to the workpiece more efficiently and uniformly.

Furthermore, due to helium’s high ionization potential, the arc requires a higher voltage, which results in a higher total arc energy. This, coupled with the arc’s diffuse, full, and broad shape (morphology), allows for increased travel speed and deeper penetration.

How to Choose TIG Shielding Gas?

When selecting shielding gases for GTA welding, argon is the most widely used due to its versatility and protective properties. For optimal results, a purity level of 99.95%-99.99% or higher is recommended to maintain consistent weld quality and reduce contamination risks.Helium is another popular choice, renowned for its high thermal conductivity, making it ideal for applications that require deep penetration and high welding speeds. However, helium’s higher cost often necessitates the use of argon-helium mixtures, typically containing 25%, 50%, 75%, or 90% helium to balance performance and affordability. Hydrogen, while beneficial for its reducing properties that help clean surface oxides, is a double-edged sword. Its high reactivity can lead to defects such as porosity or cracking when interacting with the molten pool and electrode. To mitigate these risks, hydrogen is usually combined with argon or helium, and its concentration is kept below 5%. By carefully selecting and mixing these gases, welders can achieve optimal weld quality and performance in various GTA welding applications.

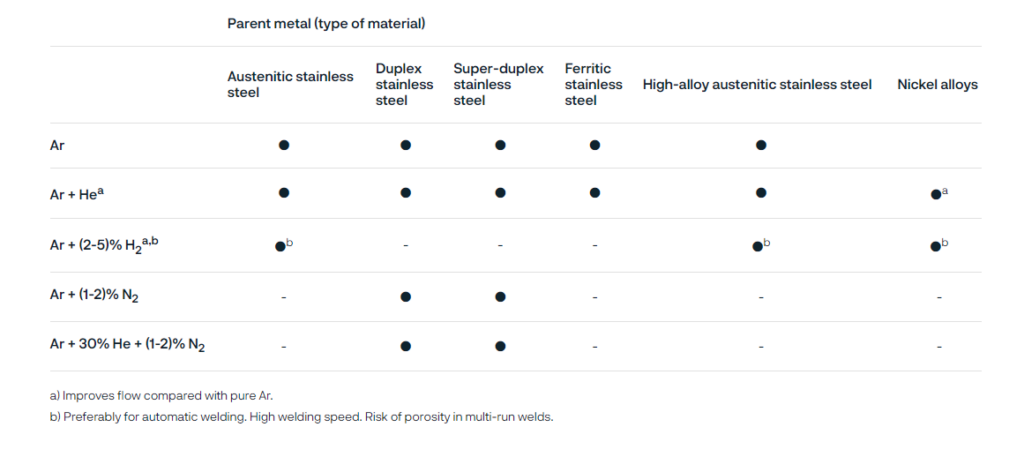

Shielding gases for TIG welding

Source:https://www.alleima.com/en/technical-center/shielding-the-weld/

Another aspect customers focus on is the gas flow rate. Controlling the flow rate is crucial as it affects the stability and effectiveness of the shielding gas. Insufficient flow can lead to gas turbulence, causing contamination and uneven shielding. On the other hand, excessive flow can waste gas and create unnecessary costs. Finding the right balance is essential, and modern welding equipment often includes flow regulators to assist welders in maintaining optimal flow rates.

As we explore the purpose and significance of an inert shielding gas in GTA welding, we begin to realize its broader implications. Beyond its technical role in creating a protective atmosphere, it symbolizes the importance of attention to detail, precision, and safety in the welding industry. Every welder recognizes that even the tiniest contamination can have catastrophic consequences. This understanding instills a sense of responsibility and meticulousness in the welding process, ensuring that each joint is executed with utmost care.

Conclusion

In conclusion, the purpose of an inert shielding gas in GTA welding is to safeguard the welding area from atmospheric contamination during the high-temperature welding process. This protective gas shield prevents defects and contamination, enabling the production of clean, high-quality welds. By providing better control and enhancing weld stability, the shielding gas improves the overall welding experience, resulting in increased productivity and reduced costs. Customers should prioritize factors such as gas purity, flow rate, and specific gas properties when purchasing a shielding gas for GTA welding. Ultimately, the use of an inert shielding gas reflects the meticulousness and precision that defines the welding industry. So, why is an inert shielding gas required for GTA welding? Because it ensures the strength, integrity, and reliability of weld joints, making them capable of withstanding the most demanding applications.