Understanding the breakdown of MIG gun parts is essential for maintenance and replacement. It helps ensure better performance, easier troubleshooting, and longer service life.

In this article, we’ll focus on the BND (Bernard compatible) 300AMP MIG Gun and provide a clear parts diagram and breakdown.

For those interested in other brands, we also offer detailed guides. If you’re looking for Tweco models, check out our Tweco MIG Gun Parts Breakdown for more information.

Table of Contents

ToggleOverview of Bernard MIG Guns Series

Bernard offers a modular MIG gun platform designed to meet a wide range of welding needs. Their current BTB (Build to Build) series integrates features from the earlier Q-Gun™, S-Gun™, and T-Gun™ models, providing a customizable system that allows welders to select the handle style, neck configuration, consumables, and cable options best suited for their work.

Understanding the overall structure is important because different component choices, especially the handle type, directly affect compatibility with other parts. In the next section, we will start with the handle assembly, which plays a key role in both ergonomics and part selection.

Handle Options and Their Impact

When using a MIG gun, the handle is the part that welders interact with the most. A comfortable handle design can significantly reduce fatigue, improve control, and contribute to more consistent welding performance, especially during long shifts or complex welds.

Bernard’s modular system offers several handle styles to fit different applications and user preferences. Each style impacts not only how the gun feels in hand but also determines certain compatibility aspects with necks, triggers, and cable connections.

Choosing the appropriate handle not only influences the feel and control of the MIG gun but also impacts the compatibility of components such as trigger switches, cable assemblies, and neck fittings.

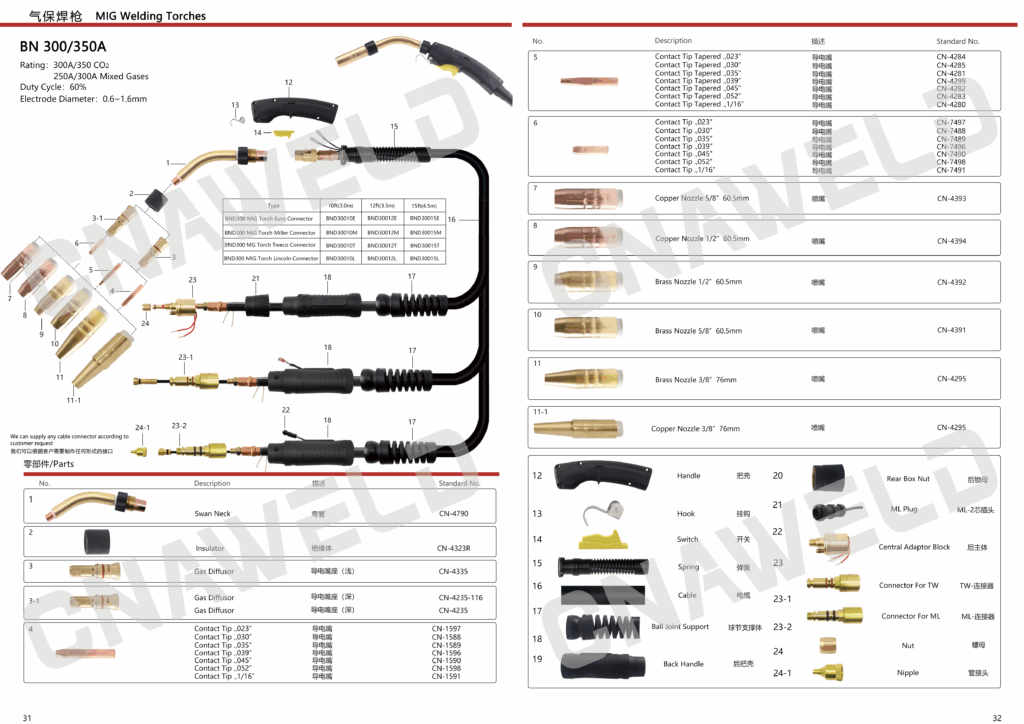

Bernard 300AMP MIG Gun Parts Diagram

To better understand the configuration of BND MIG guns, we take the 300AMP model as a standard example, which uses the B Series handle with a Standard Cable (Only O Series handle options can be used with the Steel Monocoil power cable). The following diagram provides a clear overview of the key components and their arrangement within the gun assembly.

Each part plays a role in performance, durability, and ergonomics. Thanks to the modular BTB platform, users can replace individual sections as needed without changing the entire gun.

If you would like to learn more about Bernard Style MIG guns or explore additional models and configurations, please refer to our Product Catalog or contact us directly for assistance.