When it comes to semiautomatic welding processes, GMAW (Gas Metal Arc Welding) and FCAW (Flux-Cored Arc Welding) are two popular methods that professionals often find themselves choosing between. Understanding their differences and advantages helps determine the right process for your project. This article will cover key considerations, highlighting the specific benefits and suitable applications for each method.

Table of Contents

ToggleWhat Is Semiautomatic Welding?

Before we get started,let’s first clarify what semiautomatic welding means.Semiautomatic welding means the welding equipment feeds the welding wire automatically, while the welder manually controls the movement and positioning of the welding torch. This combination provides both flexibility and consistency, making it widely used across various industries.

Advantages of GMAW:

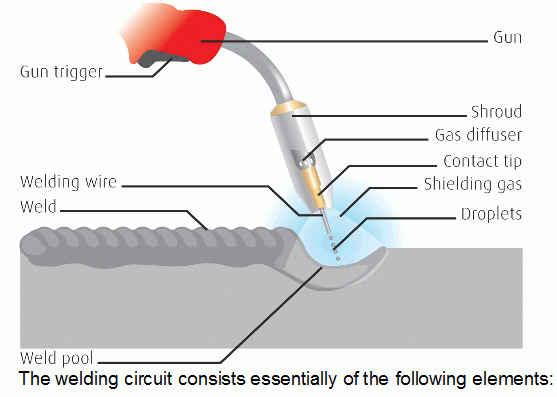

To begin with, let’s delve into the specifics of GMAW. Gas Metal Arc Welding, also known as Metal Inert Gas (MIG) welding, utilizes a solid wire electrode and a shielding gas mixture to create the arc. This welding process offers numerous advantages, such as high welding speeds, excellent weld quality, and the ability to weld a variety of materials including aluminum, stainless steel, and mild steel. GMAW is commonly used in automotive industries, shipbuilding, and general fabrication.

Advantages of FCAW:

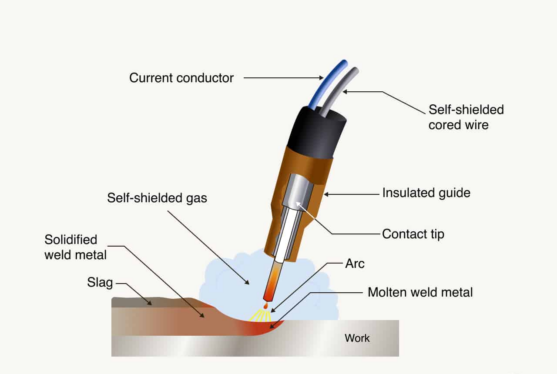

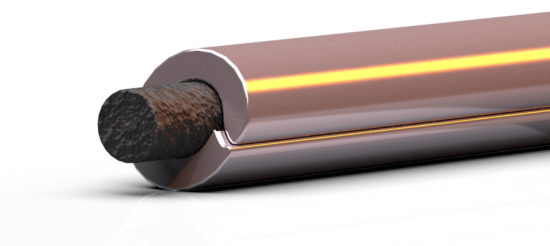

On the other hand, we have Flux-Cored Arc Welding (FCAW), which employs a tubular wire electrode filled with flux. This flux serves multiple functions, including providing protection against atmospheric contamination, reducing the need for shielding gas, and enhancing the mechanical properties of the weld. FCAW is particularly advantageous for outdoor welding, as it can effectively operate in windy or dirty conditions. Additionally, FCAW has a higher deposition rate compared to GMAW, meaning that it can achieve faster welding speeds. This makes the process suitable for large-scale industrial applications, such as structural steel fabrication, pipeline welding, and heavy equipment manufacturing.

Source:https://weldguru.com/

Comparison Between GMAW and FCAW:

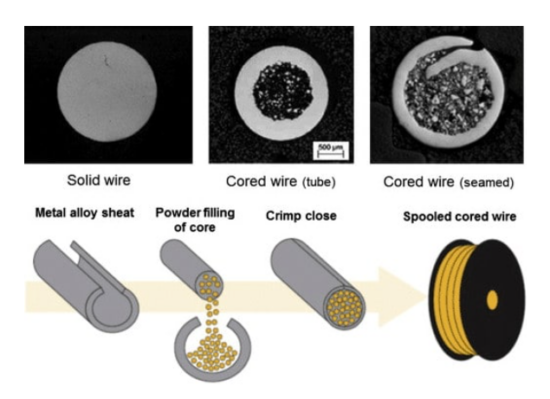

GMAW and FCAW utilize almost identical welding equipment, including welding torches, helmets, and welding machines. The primary difference lies in the electrode type: GMAW uses solid wire and relies on shielding gas stored in cylinders, while FCAW employs flux-cored wire.

This difference in wire type also dictates the welding drive rolls used: GMAW typically employs V-groove rolls for solid wire, while FCAW generally requires V-knurled rolls for flux-cored wire. Learn more about choosing the right welding drive rolls here.

A notable advantage of FCAW is that certain flux-cored wires are self-shielded and do not require external shielding gas (also called FCAW-S). This makes FCAW particularly advantageous for outdoor welding, as it eliminates the need for additional gas cylinders, reducing equipment complexity and lowering gas expenses.

When choosing between GMAW and FCAW, customers carefully consider the benefits of each process. GMAW offers versatility in welding various materials, including aluminum, stainless steel, and mild steel, with minimal adjustments. This flexibility is ideal for industries like automotive manufacturing, where different metals frequently appear on the same production line.

Flux-Core Source:http://weldnotes.com/?p=123

Meanwhile, FCAW is favored by customers needing higher deposition rates, deeper penetration, and the convenience of outdoor applications. By using self-shielded flux-cored wires, FCAW simplifies equipment requirements, reducing overall costs and enhancing portability, particularly in environments where external shielding gas would be challenging or impractical to manage.

However, FCAW generally produces more spatter compared to GMAW and requires additional time for cleaning slag after welding. Users should account for this extra step when choosing FCAW for their applications.

How to Identify Flux-Cored and Solid Wires?

To quickly identify flux-cored and solid wires, try bending the wire. Solid wire is relatively flexible and can usually be bent more than 90° multiple times without breaking. Flux-cored wire, however, typically breaks after just one or two bends. Additionally, some lower-quality flux-cored wires can be unwound by twisting the wire ends with two pairs of pliers—better-quality flux-cored wires will not easily come apart. It’s also important to note that flux-cored wires left exposed to moisture for extended periods may absorb moisture into the flux, causing potential welding issues.

Source:https://materialwelding.com/metal-cored-welding-vs-flux-cored/

Different Applications:

Apart from the specific benefits, application areas strongly influence the decision-making process for customers. In the automotive industry, where weight reduction and fuel efficiency are paramount, GMAW plays a crucial role. Due to its ability to weld lightweight materials like aluminum, GMAW is often used to join aluminum panels in the production of modern vehicle bodies. Additionally, in shipbuilding, the corrosion resistance of stainless steel is highly sought after. GMAW’s suitability for welding stainless steel allows shipbuilders to create reliable, durable, and corrosion-resistant structures.

For industries involving large-scale structures, such as construction or manufacturing, FCAW becomes the preferred choice. The fast welding speeds and high deposition rates of FCAW make it ideal for tackling heavy-duty applications. Take the example of building a bridge. The fabrication of steel girders that provide support requires efficient and strong welds. By utilizing FCAW, the welding process will be expedited, leading to increased productivity and reduced construction time.

Conclusion:

In conclusion, understanding the differences between GMAW and FCAW is essential for selecting the most suitable semiautomatic welding process. GMAW’s versatility in welding various materials makes it ideal for industries that work with a range of metals such as automotive, while FCAW’s ability to provide higher deposition rates and faster welding speeds is beneficial for heavy-duty applications like pipeline welding and large-scale structures. By considering the product benefits and application areas that align with their specific needs, customers can make an informed decision, ensuring effective results in their welding projects.

Remember, whether you choose GMAW or FCAW, both processes have their strengths and areas of expertise. It ultimately comes down to understanding your project requirements, the materials you will be working with, and aligning those factors with the advantages each process offers. So, make a wise choice when selecting between GMAW and FCAW for your semiautomatic welding projects.

FAQs: Can you run flux core wire in a MIG welder?

Yes. You will need to make a few changes to your machine, including:

- Changing the polarity. For self-shielded wire (FCAW-S), you must reverse the polarity so the gun is negative and the work clamp is positive.

- Switching the drive rolls. Use knurled V- or U-groove drive rolls.

- Not using shielding gas. The flux inside the wire creates its own gas shield.

- Using a drag (pull) technique instead of a push technique.