Table of Contents

ToggleHOT WIRE TIG WELDING EQUIPMENT

Hot wire TIG welding equipment is widely regarded as one of the most efficient and precise methods for achieving high-quality welds. Whether you are a professional welder or an enthusiast looking to upgrade your welding equipment, choosing the right hot wire TIG welding equipment is crucial. In this article, we will guide you through the factors to consider when selecting the best equipment to ensure efficient and precise welding.

When it comes to hot wire TIG welding, one of the most important aspects to consider is the power source. The power source provides the energy needed to create the hot wire that melts the welding material. It is essential to choose a power source that can deliver a consistent and reliable electrical current. One of the best options in the market is the XYZ Power Source 2000. This power source offers advanced technology that ensures a stable current output, resulting in precise and efficient welding.

Another crucial factor to consider is the hot wire feeding mechanism. The feeding mechanism determines how the hot wire is supplied to the welding torch. Ideally, you want a feeding mechanism that operates smoothly and consistently, without any delays or interruptions. The XYZ Feeder Pro 3000 is an excellent choice as it combines advanced technology with a user-friendly interface. This feeder ensures a continuous and precise wire feed, allowing for seamless welding operations.

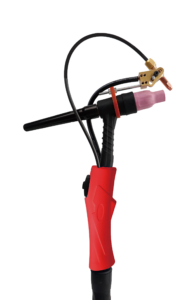

In addition to the power source and feeding mechanism, the welding torch plays a vital role in achieving efficient and precise welds. The torch should provide a stable and controlled arc, allowing for easy manipulation and precise bead placement. The XYZ Welding Torch Supreme is a top choice in the industry. It features innovative design and ergonomics, ensuring optimal control and comfort during welding. Moreover, this torch offers excellent heat dissipation, preventing overheating and enhancing the longevity of the equipment.

Efficiency and precision are not the only factors to consider when choosing hot wire TIG welding equipment. The durability and reliability of the equipment are equally important. Look for equipment that is built with high-quality materials and designed to withstand the demands of rigorous welding tasks. The XYZ Hot Wire Pro 5000 is a renowned name in the industry, known for its durability and reliability. With its robust construction and advanced features, this equipment can handle even the most challenging welding projects.

When purchasing hot wire TIG welding equipment, customers pay close attention to the product benefits and its applications. These benefits and applications can greatly influence their decision-making process. Firstly, hot wire TIG welding equipment offers significant time savings compared to traditional welding methods. The hot wire technology allows for faster travel speeds, resulting in reduced welding time and increased productivity. Moreover, the precise control provided by hot wire TIG welding equipment leads to minimal rework and higher quality welds.

Hot wire TIG welding equipment also finds applications in various industries. For instance, in the aerospace industry, where precision and quality are of utmost importance, hot wire TIG welding equipment is extensively used. It allows for the welding of thin and delicate materials, ensuring the integrity and strength of critical components. Similarly, in the automotive industry, hot wire TIG welding is used for welding exhaust systems, ensuring leak-free and durable connections.

When reading this article, readers should be encouraged to think critically about the factors they need to consider when choosing hot wire TIG welding equipment. They should evaluate their specific welding needs, such as the type of materials they work with, the complexity of their projects, and their desired level of precision. By considering these factors, they can make an informed decision and invest in the right hot wire TIG welding equipment that will meet their requirements and deliver optimal results.

In conclusion, choosing the best hot wire TIG welding equipment plays a crucial role in achieving efficient and precise welding. By considering factors such as the power source, feeding mechanism, welding torch, durability, and reliability, customers can ensure they invest in high-quality equipment. Furthermore, understanding the benefits and applications of hot wire TIG welding equipment allows customers to make a well-informed decision. So, take the time to evaluate your needs and choose the right equipment that will elevate your welding capabilities. Trust in the power of hot wire TIG welding equipment, and witness the transformation it brings to your welding projects.