Are you in the market for a welding gun but feeling overwhelmed by the numerous options available? Don’t worry! This article will guide you in choosing the perfect welding gun for your specific project, ensuring you achieve the best results with ease. We will explore the key considerations, benefits, and application areas to help you make an informed decision.

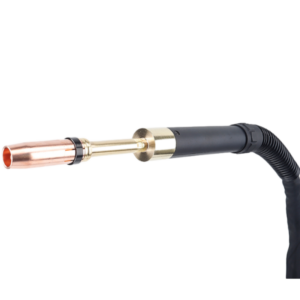

When purchasing a welding gun, there are several factors you need to consider. Firstly, determine the type of welding you will be performing. There are various types, including MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and Stick welding. Each type requires a specific type of welding gun. For instance, MIG welding guns are ideal for projects involving stainless steel, aluminum, and mild steel, while TIG welding guns are better suited for intricate and precision welds on thinner materials like aluminum and stainless steel.

The second consideration is the thickness of the metals you will be welding. Different welding guns have varying amperage capabilities, which determine their welding capacity. For example, a welding gun with a higher amperage is suitable for thicker metals, while a lower amperage gun is better for thinner materials. Understanding the thickness of your project will help you select the appropriate welding gun for efficient and effective welding.

Additionally, take into account the project’s location. Will you be working in tight spaces or on large structures? This influences the length and flexibility of the welding gun you choose. Shorter guns are advantageous in confined spaces, allowing for better maneuverability and access. On the other hand, longer guns are beneficial for welding on larger structures where reach is important.

Now let’s delve into the benefits and applications of different types of welding guns. MIG welding guns are highly versatile and commonly used in automotive repairs, fabrication, and construction. Their ability to create strong, clean welds on various metals makes them a popular choice among DIY enthusiasts and professionals alike.

TIG welding guns, renowned for their precision, are widely employed in industries such as aerospace, electronics, and jewelry making. The fine control they offer allows for delicate welds and reduces the need for additional post-welding cleanup. These guns are also ideal for welding exotic metals like titanium and magnesium.

Stick welding guns, also known as Shielded Metal Arc Welding (SMAW) guns, excel in outdoor applications and heavy-duty projects. They are widely used in the construction industry for welding thick materials and are particularly suitable for welding in challenging and windy conditions. The simplicity and portability of stick welding guns make them a popular choice for remote locations and repair works.

By carefully considering these factors and understanding the benefits and applications of various welding guns, you can make an informed decision that aligns with your project’s requirements. Remember, it is essential to prioritize safety when using welding guns. Ensure you have the necessary protective gear, such as welding helmets, gloves, and appropriate clothing, to safeguard yourself from potential hazards.

In conclusion, choosing the right type of welding gun for your project significantly impacts the quality and efficiency of your welding. By considering the type of welding, thickness of metals, and project location, you can narrow down your options and make a suitable choice. MIG, TIG, and Stick welding guns have their unique benefits and applications, catering to a wide range of industries and projects. Now armed with this knowledge, go ahead and select the perfect welding gun that will make your project a resounding success.