Table of Contents

ToggleHow to Clean Metal Before Welding

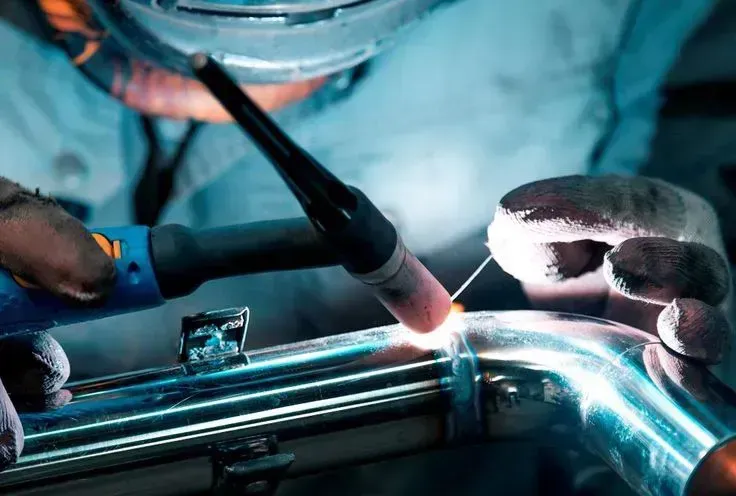

Cleaning metal before welding is crucial to ensuring solid and high-quality welds. Contaminants like rust, oil, and dirt can lead to weak joints and defects. This article provides a comprehensive guide on cleaning metal before welding for best results.

Why Clean Metal Before Welding?

Contaminants on metal surfaces can cause several issues:

Porosity:

Trapped gases create holes in the weld.

Weak Joints:

Contaminants prevent proper fusion.

Corrosion:

Residual debris can lead to rust.

Understanding how to clean metal before welding is essential to avoid these problems.

Tools and Materials Needed

To effectively clean metal before welding, gather the following tools and materials:

Wire brushes

Sandpaper or grinding wheels

Degreasers or acetone

Clean cloths

Safety gear (gloves, goggles, mask)

Steps on How to Clean Metal Before Welding

1. Assess the Metal Condition

Before starting, assess the metal to determine the level of cleaning required. Rusty or heavily oiled metals need more thorough cleaning.

2. Remove Surface Contaminants

Use a Wire Brush or Grinder:

To remove rust and paint, use a wire brush or a grinder. This mechanical action helps strip the surface back to bare metal.

Sandpaper:

For finer cleaning, sandpaper can smooth the surface and remove minor impurities.

3. Degrease the Metal

Apply a Degreaser:

Oils and grease can be stubborn contaminants. Use a commercial degreaser or acetone to clean these residues. Ensure you wipe the surface thoroughly with a clean cloth.

4. Clean with Acetone

Final Wipe:

Acetone is excellent for removing any remaining residues. Soak a cloth in acetone and wipe down the metal. This step is critical in how to clean metal before welding to ensure a pristine surface.

5. Inspect the Surface

Visual Check:

After cleaning, visually inspect the metal. It should be shiny and free from any visible contaminants.

Tips for Effective Cleaning

Safety First:

Always wear safety gear when cleaning metal. Dust and chemical fumes can be hazardous.

Consistent Maintenance:

Regular maintenance of cleaning tools ensures they perform effectively.

Choose the Right Tools:

Different metals may require specific brushes or cleaners.

Common Mistakes and How to Avoid Them

Skipping the Cleaning Process:

Forgoing cleaning can lead to weld failures. Always prioritize this step.

Using Dirty Tools:

Using contaminated brushes or cloths can reintroduce dirt. Keep tools clean and replace them when needed.

Rushing the Process:

Take your time to ensure thorough cleaning. Hastiness can compromise weld quality.

Conclusion

Understanding how to clean metal before welding is vital for any welder aiming for high-quality results. Proper cleaning removes rust, oil, and dirt, leading to more robust and more reliable welds. Following the outlined steps and tips, you can achieve a clean metal surface ready for welding, ensuring the best possible outcomes in your projects.