How to Create Different Welding Bead Patterns: A Comprehensive Guide for Welders

Welding is a skill that requires precision, technique, and creativity. One aspect of welding that often captures the attention of both novice and experienced welders is the creation of different welding bead patterns. These patterns not only enhance the aesthetics of the weld but also contribute to its strength and performance. In this comprehensive guide, we will explore various welding bead patterns, their application areas, and the benefits they offer. So, grab your welding helmet and get ready to dive into the world of captivating welds!

Table of Contents

ToggleTypes of Welding Beads

Stringer Bead

When it comes to welding bead patterns, there are several options available to welders. One of the most common patterns is the straight line or stringer bead. As the name suggests, this pattern involves creating a straight welding bead along the joint. It is often used in simple welds where strength is the primary concern. For example, when joining two metal plates together, a straight line bead ensures a strong and sturdy connection.

Weave Bead

Another popular welding bead pattern is the weave bead. This pattern involves moving the welding torch in a zigzag motion, creating a wider and layered weld. The weave bead pattern is commonly used in situations where additional strength and reinforcement are required. For instance, when welding structural beams or pipes, a weave bead provides improved rigidity and durability.

Circular Bead

In addition to the straight line and weave bead patterns, welders can also experiment with circular bead patterns. These patterns involve creating welds in circular or semi-circular motions. Circular bead patterns are often utilized in situations where the weld joint requires extra flexibility or stress relief. For example, in automotive applications, circular bead patterns are commonly employed when joining exhaust pipes or mufflers, allowing for better movement and unrestricted flow of gases.

Stack of Dimes Bead

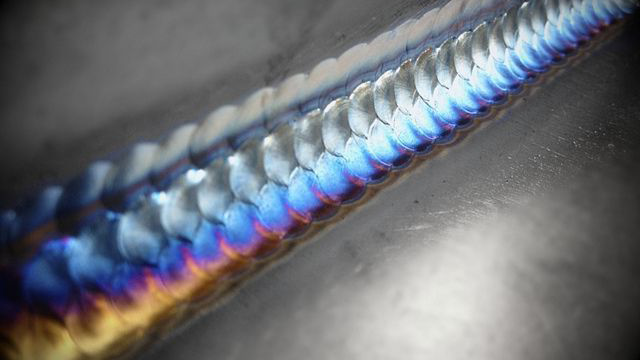

One intriguing welding bead pattern is the “stack of dimes” pattern. This pattern gets its name from the appearance of stacked dimes, as the weld beads overlap each other. The stack of dimes pattern is highly sought after for its decorative and aesthetically pleasing effect. It is often found in artistic welding projects, such as sculptures or ornamental ironwork, where the weld itself becomes a work of art.

Now that we have explored some of the different welding bead patterns, let’s discuss the product benefits and application areas that welders should consider when purchasing welding bead patterns.

First and foremost, welders should pay attention to the strength and integrity of the weld produced by the bead pattern. Each pattern has its own unique characteristics and affects the weld’s performance differently. For instance, a weave bead pattern provides additional reinforcement and strength, making it ideal for structural applications. On the other hand, a circular bead pattern offers increased flexibility and stress relief, suitable for joints that may experience movement or vibration.

Secondly, welders should consider the efficiency and speed of welding with different bead patterns. Some patterns, such as the straight line bead, are easier to execute and require less time and effort. This simplicity makes them suitable for high-volume welding projects where speed is crucial. However, more intricate patterns like the stack of dimes may require additional attention to detail and take longer to complete.

Moreover, welders should take into account the appearance and aesthetics of the weld created by the bead pattern. Certain projects, such as architectural structures or art pieces, demand visually appealing welds. In such cases, patterns like the stack of dimes can add an element of beauty and artistic flair to the final product.

Additionally, welders should consider the compatibility of the bead pattern with the materials being welded. Different materials have varying welding requirements and characteristics. Before purchasing a welding bead pattern, it is essential to ensure that it is suitable for the specific material and welding process being used.

Finally, customers should also assess the affordability and availability of the welding bead patterns. While some patterns may offer unique benefits, they may be comparatively more expensive or difficult to source. It is important to strike a balance between the desired bead pattern and its availability within budget constraints.

This comprehensive guide has explored the fascinating world of welding bead patterns. By understanding different patterns and their application areas, welders can create unique and impactful welds. Whether it is the strength of the weave bead, the flexibility of the circular bead, or the beauty of the stack of dimes pattern, each welding bead pattern offers its own advantages. So, the next time you pick up your welding torch, don’t be afraid to unleash your creativity and experiment with various welding bead patterns to leave a lasting impression.