Table of Contents

ToggleMAG Welding Techniques

MAG welding, also known as Metal Active Gas welding, is a popular welding technique used in various industries. It involves the use of a consumable wire electrode and a shielding gas to create strong and durable welds. If you’re looking to enhance your welding skills and become proficient in MAG welding techniques, this comprehensive guide will provide you with the necessary knowledge and steps to achieve mastery.

Understand the Basics of MAG Welding:

Before diving into the intricacies of MAG welding techniques, it’s essential to grasp the fundamental principles. Familiarize yourself with the equipment used, such as the power source, wire feeder, welding gun, and shielding gas supply. Learn about the different types of shielding gases and their applications in MAG welding.

Ensure Proper Safety Measures:

Safety should always be a top priority in welding. When practicing MAG welding techniques, wear appropriate personal protective equipment (PPE), including a welding helmet, gloves, and flame-resistant clothing. Ensure proper ventilation in your workspace to minimize exposure to fumes and gases.

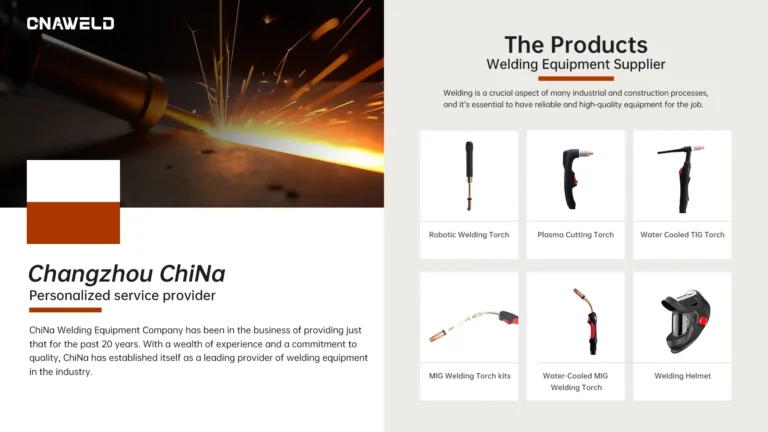

Select the Right Equipment and Materials:

To master MAG welding, you need the right equipment and materials. Choose a suitable welding machine that matches your skill level and the intended application. Select the appropriate wire electrode based on the type of metal you are welding, and ensure it is compatible with your welding machine. Similarly, choose the correct shielding gas based on the material being welded.

Prepare Your Workpiece:

Proper preparation of the workpiece is crucial for successful MAG welding. Clean the surface to be welded, removing any dirt, rust, or contaminants. Use a wire brush or grinding tool to achieve a clean and smooth surface, ensuring good weld penetration and adhesion.

Set Up Your Welding Parameters:

Accurate welding parameters are essential for achieving high-quality welds. Adjust the voltage, wire feed speed, and shielding gas flow rate according to the material thickness, wire diameter, and joint configuration. Follow the manufacturer’s recommendations and conduct test welds to fine-tune your settings.

Master Welding Techniques:

Developing proficiency in MAG welding techniques requires practice and patience. Experiment with different welding positions, such as flat, horizontal, vertical, and overhead, to gain versatility. Learn various joint configurations, including butt joints, lap joints, and fillet welds. Focus on maintaining a steady hand, controlling the travel speed, and achieving proper weld bead shape and size.

Troubleshoot Welding Issues:

During your welding journey, you may encounter challenges or welding defects. Common issues include porosity, spatter, improper penetration, and undercutting. Learn to identify these problems and understand their root causes. Implement corrective measures such as adjusting parameters, cleaning the workpiece thoroughly, or modifying your welding technique.

Practice Welding on Different Materials:

To become a well-rounded MAG welder, practice welding on a variety of materials. Experiment with carbon steel, stainless steel, aluminum, and other alloys. Each material has its unique characteristics and requires specific welding techniques. By gaining experience with different materials, you’ll expand your skills and versatility as a MAG welder.

Seek Guidance and Learn from Experts:

Don’t hesitate to seek guidance and mentorship from experienced welders. Join welding communities, forums, or local welding associations to connect with professionals and learn from their expertise. Attend workshops, training programs, or seminars to further enhance your knowledge of MAG welding techniques.

Continuously Improve and Refine Your Skills:

Mastery of MAG welding techniques is an ongoing process. Continuously strive to improve your skills by seeking new challenges and projects. Stay updated with the latest advancements in equipment, materials, and welding processes. Regularly evaluate your welds and seek feedback from experts to identify areas for improvement.

Mastering MAG welding techniques requires a combination of theoretical knowledge, practical experience, and dedication. By understanding the basics, prioritizing safety, selecting the right equipment, and practicing various welding techniques, you can enhance your skills and become proficient in MAG welding. Remember to continuously learn, seek guidance, and refine your skills to achieve mastery in this versatile welding technique.