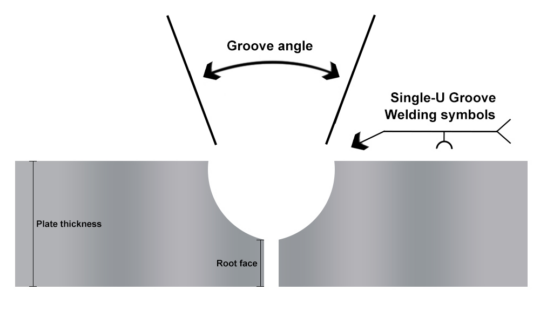

U-groove welds are a type of weld joint commonly used in welding applications. This particular type of weld joint is characterized by its U-shaped groove, which provides several advantages over other types of weld joints. In this article, we will delve into the details of U-groove welds, their applications in welding, and the benefits they offer to customers.

When it comes to welding, choosing the right joint design is crucial for ensuring a strong and reliable weld. U-groove welds are particularly popular due to their versatility and ability to accommodate a wide range of materials and thicknesses. The unique shape of the U-groove creates a space for the weld pool to penetrate and fuse with the base metals, resulting in a secure bond.

One of the main benefits of U-groove welds is their ability to provide deep penetration. The depth of penetration is vital in welding applications, especially when joining thick materials. The U-groove allows for a larger weld pool, ensuring proper fusion between the base metals. This deep penetration capability enhances the overall strength and integrity of the weld, making it suitable for demanding applications such as structural steel fabrication, pipeline construction, and pressure vessel manufacturing.

Furthermore, U-groove welds offer excellent control over the weld bead profile. Welders can easily manipulate the shape and size of the weld bead by adjusting the groove dimensions. This flexibility allows for the production of welds with specific characteristics, such as concave or convex profiles. For instance, in automotive manufacturing, welds with flat or slightly concave profiles are preferred as they offer better aesthetics and improve the overall aerodynamics of the vehicle.

In addition to their versatility and control over weld bead profiles, U-groove welds also provide increased accessibility. The shape of the groove allows welders to easily reach the joint, ensuring proper penetration and minimizing the risk of incomplete fusion. This accessibility is particularly important in applications where access to the joint is limited, such as shipbuilding, aerospace manufacturing, and repairs in confined spaces.

Customers seeking U-groove welds should pay attention to several factors when making a purchase. Firstly, it is important to consider the material and thickness of the components being welded. U-groove welds are suitable for a wide range of materials, including carbon steels, stainless steels, aluminum, and alloys. However, the dimensions of the groove must be carefully selected to ensure proper fusion.

Another important aspect to consider is the welding process being used. The choice of welding process, such as gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), or shielded metal arc welding (SMAW), can influence the design and dimensions of the U-groove. It is crucial to select the appropriate welding process and adjust the groove dimensions accordingly to achieve the desired weld quality.

Furthermore, customers should also consider the application requirements and the specific demands imposed on the weld joint. For example, in structural steel fabrication, the weld strength and integrity play a critical role in ensuring the safety and stability of the structure. In this case, using a U-groove weld with proper penetration and fusion is essential to meet the desired structural integrity standards.

In conclusion, U-groove welds are a versatile and reliable choice for various welding applications. Their ability to provide deep penetration, control over weld bead profiles, and increased accessibility makes them highly desirable in industries such as construction, automotive, aerospace, and manufacturing. Customers seeking U-groove welds should consider factors such as material type, thickness, welding process, and application requirements to ensure the best results. With their numerous benefits, U-groove welds continue to be a valuable tool for welders in achieving strong and dependable joints.