Welding is a widely used technique in various fields, enabling the joining of different materials by melting and fusing them together. To achieve this, welding torches are equipped with welding nozzles, which play a crucial role in the welding process. These nozzles come in different shapes and sizes, designed to meet the specific requirements of different welding applications.

So, what exactly are welding nozzles? Welding nozzles are attachments that are usually made of copper or brass and are installed on the front end of a welding torch. They serve multiple purposes, including directing the flow of gas and electrode wire, controlling the shape and size of the weld pool, and protecting the electrode and weld from external contaminants.

The functionality of welding nozzles can be best explained by delving into their various components and their working mechanism. Let’s take a closer look:

1. Gas Flow Control: One of the key functions of a welding nozzle is to regulate the flow of shielding gas, which is used to protect the welding zone from atmospheric contamination. The design of the nozzle influences the pattern and direction of the gas flow.

For instance, when MIG welding, the welding nozzle directs a steady flow of shielding gas around the arc, preventing oxidation and ensuring a high-quality weld. In this case, customers would look for welding nozzles that provide optimal gas coverage and minimize the risk of porosity and defects in the weld.

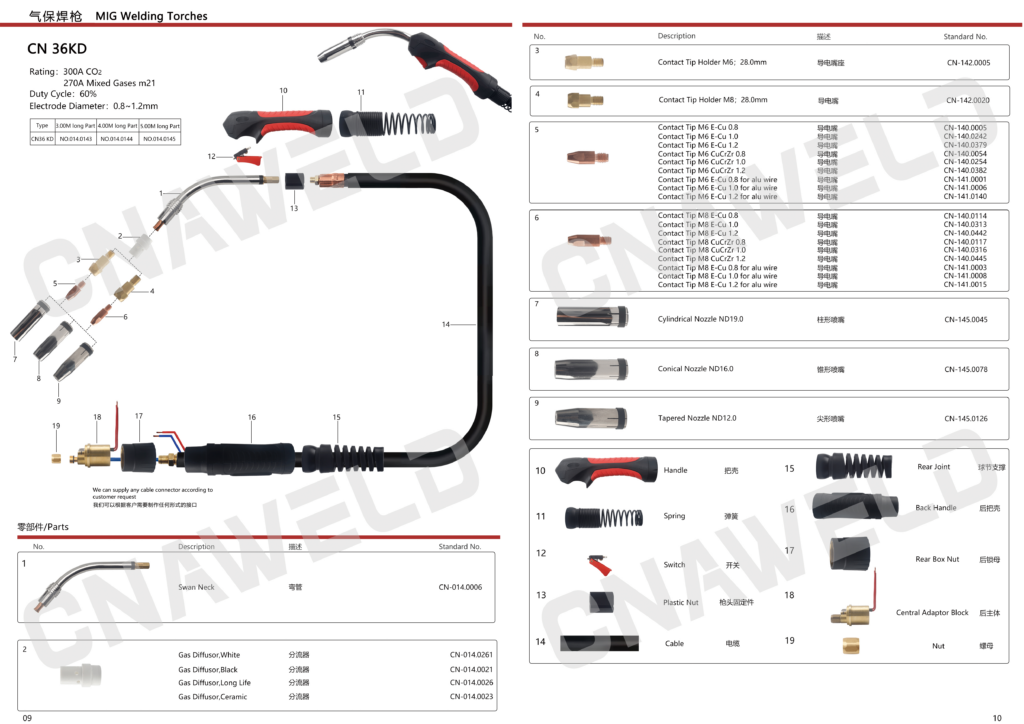

In MIG welding, nozzle shape directly affects gas coverage and weld quality. As shown on the CNAWELD Binzel 36KD MIG welding torch, there are three common nozzle types:

Cylindrical Nozzle Ideal for high amperage welding; handles strong gas flow and allows easier cleaning around the tip and inner walls.

Conical Nozzle – Focused gas flow with wider coverage; ideal for zinc-coated metals and stable shielding.

Tapered Nozzle – Narrow tip for tight spaces; gas coverage is tighter and more concentrated.

CNAWELD Binzel Style 36KD MIG Welding Torch

2. Electrode Wire Control: Another essential aspect of welding nozzles is their role in guiding the electrode wire to the desired location. The nozzle has a central hole through which the wire passes, ensuring its precise alignment with the weld pool. It also helps to maintain a consistent distance between the nozzle and the workpiece, known as the contact tip-to-work distance.

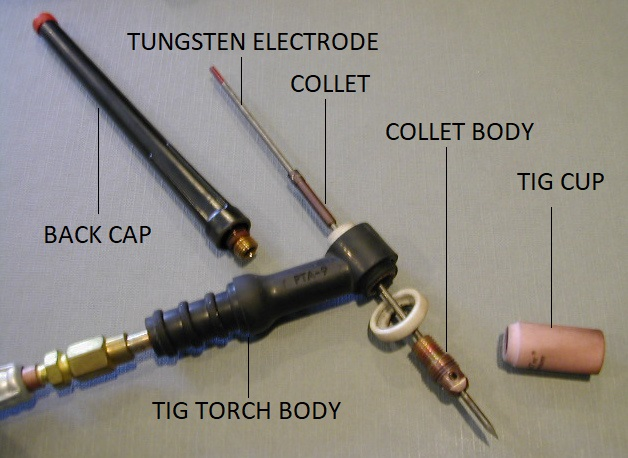

For instance, in TIG welding, the nozzle acts as a guide for the tungsten electrode, ensuring accurate placement and stability. Customers seeking TIG welding nozzles would prioritize those that offer excellent wire control and allow for precise welding in intricate or hard-to-reach areas.

3. Weld Pool Formation: Welding nozzles also contribute to the formation and control of the weld pool. By dictating the size and shape of the molten metal, they influence the overall quality and strength of the weld. Nozzles with different orifice sizes can achieve varying levels of penetration and bead width, providing flexibility in meeting specific welding requirements.

Consider a customer looking for welding nozzles for submerged arc welding, a process commonly used in heavy metal fabrication. They would seek nozzles that create a deep and narrow weld pool, ensuring strong fusion between thick metal plates.

4. Protective Barrier: Lastly, welding nozzles act as a protective barrier, shielding the electrode and weld pool from external contaminants, such as dust, dirt, and sparks. They prevent these particles from interfering with the welding process or compromising the integrity of the weld.

For example, when using a plasma arc welding nozzle, the nozzle helps to confine the plasma arc within a controlled area. This containment prevents sparks and metal spatter from causing damage to the surrounding environment or adjacent components. Customers focused on plasma arc welding would value nozzles that provide effective protection and minimize the risk of contamination.

When purchasing welding nozzles, customers carefully evaluate the product benefits and consider their specific application areas. They seek welding nozzles that offer precise gas flow control, excellent wire guidance, and reliable weld pool formation. The ability to protect the welding environment and ensure high-quality welds are also significant factors that customers pay attention to.

In conclusion, welding nozzles are integral components of welding torches, enabling efficient and precise welding processes. By controlling gas flow, electrode wire guidance, weld pool formation, and providing a protective barrier, these nozzles contribute to achieving optimal welding results. Customers understand the importance of selecting the right welding nozzles for their applications, taking into account the specific benefits and desired outcomes. So, next time you observe a welding operation, remember the essential role played by the welding nozzles in creating strong, reliable, and expertly executed welds.