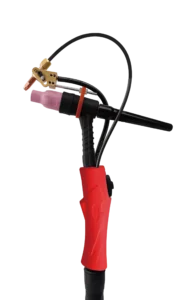

When it comes to welding, a crucial tool that stands out is the Tig Torch. Its versatility, precision, and user-friendly design make it a preferred choice for many welding enthusiasts.

What is a Tig Torch?

A Tig Torch, short for Tungsten Inert Gas Torch, is a specialized welding tool that employs a non-consumable tungsten electrode to create a high-quality weld. It is commonly used with the Gas Tungsten Arc Welding (GTAW) process, also known as Tungsten Inert Gas (TIG) welding. This torch is uniquely designed to offer precise control over the welding arc, resulting in impeccable welds.

Application Areas for Tig Torch:

1. Automotive Industry: One prominent application area for a Tig Torch is the automotive industry. With its ability to produce highly aesthetic and clean welds, TIG welding using a Tig Torch is ideal for automotive bodywork repairs, exhaust systems, and fabrication of roll cages. The precise control provided by the Tig Torch enables welders to work on delicate automobile parts without compromising their structural integrity.

2. Aerospace Industry: The aerospace industry extensively relies on Tig Torch welding due to its ability to create consistently strong and reliable welds. From manufacturing aircraft components like engine parts, fuel tanks, and exhaust systems to intricate repair jobs, the Tig Torch guarantees welds of superior quality, minimizing the risk of structural failures.

3. Artistic Creations: Tig Torch welding is not limited to industrial applications alone. It has become increasingly popular among artists and craftsmen for creating intricate metal sculptures and decorative pieces. Artists favor the Tig Torch due to its exceptional control over the welding arc, enabling them to realize their creative visions with precision and finesse.

Effective Utilization of a Tig Torch:

1. Proper Tungsten Selection: Selecting the right tungsten electrode is crucial for achieving optimal welding results. The choice of tungsten depends on the material being welded. While pure tungsten is suitable for aluminum and magnesium alloys, thoriated or ceriated tungsten works best for stainless steel and exotic metals.

2. Controlling the Arc Length: Maintaining an appropriate arc length is vital for obtaining desirable welds. A consistent arc length of approximately 1.5 to 2 times the electrode diameter should be maintained throughout the welding process. This ensures proper heat control and minimizes the chance of defects or distortions in the weld.

3. Shielding Gas Selection: The choice of shielding gas greatly influences the quality and strength of the weld. For most applications, argon gas is commonly used as it provides excellent protection against atmospheric contamination.

4. Proper Torch Control: Holding the Tig Torch correctly and maneuvering it smoothly is essential for achieving accurate welds. The welder should practice precise hand movement and maintain a steady travel speed to ensure a uniform and smooth bead.

As we conclude, the Tig Torch proves to be an indispensable tool in the welding industry, offering impeccable precision, versatility, and control.

Whether it is automotive repairs, aerospace welding, or artistic creations, the Tig Torch empowers welders to achieve outstanding results, making it a valuable investment for all welding enthusiasts.