Table of Contents

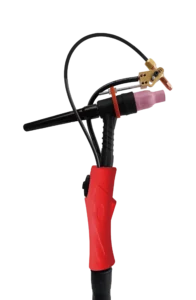

Togglehot wire TIG torch

In the world of welding, the hot wire TIG torch has quickly gained a reputation as a game-changer. This innovative tool offers a range of benefits that have captivated both professional welders and hobbyists alike. From its ability to enhance productivity to its versatility, the hot wire TIG torch has become a must-have for those seeking to take their welding projects to new heights. In this article, we will delve into the various features and advantages of this remarkable tool, as well as explore its applications and why it is a top choice for many customers.

One of the most notable benefits of the hot wire TIG torch is its ability to significantly increase welding speed. By utilizing a heated wire in addition to the traditional TIG welding process, the hot wire TIG torch allows for faster deposition rates. This means that welders can complete their projects in a shorter amount of time, increasing their overall productivity. For instance, imagine having to weld a series of intricate joints on a complex structure. With the hot wire TIG torch, you can achieve the desired results in a fraction of the time it would take using conventional TIG welding techniques.

Moreover, the hot wire TIG torch also offers exceptional control, enabling welders to achieve high-quality welds with precision and accuracy. The added heat from the wire creates a buttery smooth weld pool, reducing the likelihood of defects and ensuring a strong bond between the metals. This level of control is particularly crucial for applications that require intricate welding, such as aerospace and automotive industries. With the hot wire TIG torch, welders have the capability to create flawless welds even on delicate materials, giving them an advantage in industries where precision is paramount.

Another advantage of the hot wire TIG torch is its versatility. This tool can be used with a wide range of materials, including stainless steel, aluminum, and even exotic alloys. Whether you are working with thin or thick materials, the hot wire TIG torch can handle it all. This versatility makes it an indispensable tool in industries like shipbuilding, where different materials and thicknesses need to be joined together seamlessly. So, whether you are a professional welder or a DIY enthusiast, the hot wire TIG torch provides you with the flexibility and adaptability you need to tackle various projects with ease.

Now, let’s dive into the applications where the hot wire TIG torch truly shines. One area where this tool excels is in the welding of pipes and tubes. Whether it is for industrial pipelines or plumbing systems, the hot wire TIG torch offers precise control and reliability, ensuring leak-free and durable joints. In addition, the hot wire TIG torch is also widely used in the fabrication of pressure vessels, tanks, and boilers. Its ability to create strong, defect-free welds makes it an ideal choice for these critical applications.

Moreover, the hot wire TIG torch plays a crucial role in the manufacturing of aerospace components. From welding aircraft structures to joining thin sheets of aluminum for aircraft skins, this tool enables the production of reliable and lightweight parts. Its ability to weld intricate joints with minimal distortion and high-quality results ensures that the stringent requirements of the aerospace industry are met.

Another area where the hot wire TIG torch finds its application is in the automotive industry. From race cars to luxury vehicles, this tool is used for various welding tasks, such as joining chassis components and body panels. The hot wire TIG torch’s ability to provide exceptional control and create strong welds contributes to the safety and durability of automotive structures.

Furthermore, the hot wire TIG torch is also a popular choice for welding applications in the energy sector. Whether it is for the construction of pipelines or the fabrication of components for power plants, this tool’s ability to handle different materials and deliver high-quality welds under demanding conditions is invaluable. Its reliability ensures the integrity and longevity of the structures that are vital for the energy industry.

In conclusion, the hot wire TIG torch represents a significant advancement in the world of welding. Its ability to increase productivity, provide exceptional control, and offer unmatched versatility make it a sought-after tool for professionals and enthusiasts alike. Whether you are working on pipes, aerospace components, automotive structures, or energy-related projects, the hot wire TIG torch offers the precision and reliability you need. So, embrace this remarkable tool, and elevate your welding projects to new levels of excellence.