目录

切换介绍:

焊接是金属加工行业中备受追捧的技能,可以制造坚固耐用的结构。值得关注的一种特殊技术是方形槽焊接,它可以将金属部件牢固地连接在一起。在本综合指南中,我们将深入研究如何创建方形槽焊缝。通过了解这种焊接方法的优点和应用,您可以提高焊接技能并自信地应对具有挑战性的项目。

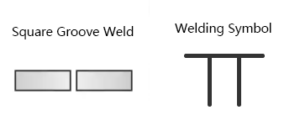

Square Groove Weld/Symbol

Source:https://www.keyence.com/ss/products/measure/welding/trouble/groove.jsp

定义方形坡口焊缝:

A square groove weld is a type of weld joint created by filling the gap between two flat,parallel metal pieces with weld metal. This method requires less filler material, resulting in minimal deformation. However, due to its geometry, square groove welds are less suited for thick plates. Despite this limitation, they are commonly used in applications where precision and minimal material distortion are crucial, such as in the fabrication of storage tanks, pressure vessels, lightweight structures, and machinery, where smaller welding volumes are preferred.

Square Groove Weld

Source:https://www.youtube.com/watch?v=lEv57KVKdbs

流程:

要创建方形坡口焊缝,请按照以下步骤操作:

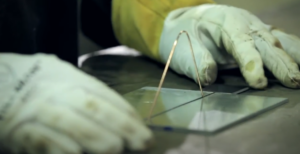

步骤 1:准备金属

Clean and Prepare the Materials for Square Groove Welding To achieve a perfect square groove weld, it’s crucial to thoroughly clean the material surfaces. Remove any debris, rust, or oil as these impurities can lead to weld defects, weakening the final product. Use a wire brush or grinding tool for optimal cleaning results. Once clean, ensure the materials are correctly positioned with enough space for the welding electrode to easily access the groove base, which is essential for strong joint penetration.

Cleaning Before Welding

第 2 步:确定凹槽角度

坡口角度决定了接头的深度和形状。它通常通过斜角来测量,斜角是两个斜边形成的角度。方形坡口焊缝最常见的坡口角度是 45 度、60 度和 90 度。坡口角度的选择取决于焊接金属的厚度和类型。

步骤 3:切割凹槽

要创建坡口,请使用切割工具(例如磨床或等离子切割机)按照预定的坡口角度进行切割。注意进行精确、干净的切割,确保坡口尺寸符合焊接规格。

步骤 4:装配对齐

接下来,必须准确对齐两块金属。此步骤可确保最终焊接具有适当的强度和完整性。使用夹具或固定装置将工件固定到位,确保它们齐平并对齐后再继续。

Fit-Up Alignment

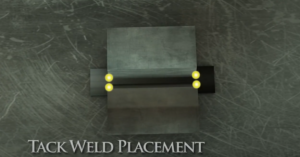

步骤5:点焊

点焊涉及进行临时焊接,以在最终焊接过程中将金属件固定到位。此步骤有助于保持正确的对齐并防止任何移动或变形。点焊应小心进行,确保它们足够坚固以将零件固定在一起,但在最终焊接过程中易于拆除。

Tack Welding(Learn more about this skills)

步骤6:焊接技术

Now comes the crucial stage of creating the square groove weld.Several welding techniques can be used, including Shielded Metal Arc Welding (SMAW), Gas Metal Arc Welding (GMAW), and Flux-Cored Arc Welding (FCAW). Among these, Gas Metal Arc Welding (GMAW) is highly recommended for its efficiency and precision. For optimal results, consider using the MMT/PMT52W Water Cooled MIG Torch from CNAWELD. This high-performance MIG torch provides excellent heat control and arc stability, ensuring superior penetration and fusion during the welding process.

The ergonomic design of the MMT/PMT52W minimizes wrist strain, allowing welders to maintain precision over extended periods. Whether you’re working on thin sheets or heavier sections, this torch offers the reliability and durability needed for high-quality square groove welds. Explore the MMT/PMT52W Water Cooled MIG Torch today for enhanced performance in your GMAW applications.

CNAWELD KEMPPI PMT 52W

步骤 7:焊接后工序

焊接完成后,使用钢丝刷或除渣锤清除所有熔渣、飞溅物或其他焊接残留物。如有必要,打磨焊接区域,确保表面光滑美观。最后,检查焊缝是否有任何缺陷或不连续性,确保其符合所需的质量标准。

Next, inspect the weld for defects or discontinuities to ensure it meets the required quality standards. This can be done using Basic NDT (Non-Destructive Testing) Methods such as:

- Visual Testing (VT): A straightforward inspection method to identify surface-level imperfections.

- Radiographic Testing (RT) or X-ray: Used to detect internal flaws in the weld.

- Ultrasonic Testing (UT): Effective for identifying internal discontinuities by transmitting high-frequency sound waves through the weld.

- Magnetic Particle Testing (MT): Suitable for detecting surface and slightly subsurface defects in ferromagnetic materials.

- Liquid Penetrant Testing (PT): A simple yet effective method to identify surface-breaking defects by applying a dye or fluorescent penetrant.

By following these steps, you can ensure the weld meets structural integrity and quality requirements, providing a durable and reliable joint.

优点和应用:

方形槽焊缝具有多种优势,在各种应用中都十分受欢迎。首先,这些焊缝具有出色的强度和承载能力,可确保焊接部件的结构完整性。此外,方形槽焊缝具有出色的抗疲劳性,非常适合承受重复应力的机械。此外,与其他类型的焊缝相比,方形槽焊缝所需的焊接材料相对较少,从而节省大型项目的成本。

方形槽焊缝的应用范围广泛,涉及建筑、制造和运输等行业。在建筑行业,这些焊缝通常用于制造钢架、梁和柱。在制造业,方形槽焊缝可用于生产重型机械、设备和车辆。最后,这些焊缝在桥梁和其他基础设施项目的制造中至关重要,可确保其稳定性和安全性。

引人深思的结论:

总之,掌握方形槽焊缝的制作技术是金属加工行业的一项宝贵技能。通过遵循上述综合指南,您可以自信地进行需要坚固耐用接头的焊接项目。了解方形槽焊缝的优点和应用可以让您了解它们在各个行业中的重要性。因此,下次您开始焊接项目时,请记住方形槽焊缝的威力及其创建持久可靠连接的能力。挑战自己,进一步完善您的焊接技能,并在不断扩展的金属制造领域中开启新的机会。