目录

切换为什么 GTA 焊接需要惰性保护气体?

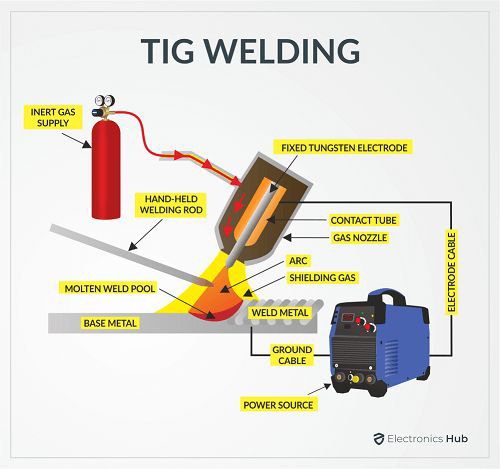

Gas Tungsten Arc (GTA) welding, also known as Tungsten Inert Gas (TIG) welding, is a popular welding process used in various industries, including automotive and fabrication. In GTA welding, an inert shielding gas is essential for achieving high-quality welds. But what exactly is the purpose of this shielding gas and why is it required? Let’s delve deeper into this topic to understand its significance.

TIG Welding Process Source:Electronics Hub

Protecting the Weld Metal

从本质上讲,GTA 焊接中使用惰性保护气体的目的是保护焊接区域免受大气污染。在焊接过程中,钨电极和被焊接金属之间会形成高能电弧。该电弧会产生强烈的热量,熔化电极和母材。如果暴露在周围的空气中,熔融的金属和电极会与氧气和氮气等大气气体发生反应,导致焊缝出现缺陷,并损害其强度和完整性。

为了解决这一潜在问题,人们使用惰性气体在焊接熔池周围形成保护性气氛。惰性气体(例如氩气和氦气)在化学上不活泼,这意味着它们不易与其他物质发生反应。当这些气体被引入焊接环境时,它们会形成稳定的屏蔽,防止大气气体进入。该屏蔽充当屏障,确保熔融金属和电极与空气隔离,从而最大限度地降低缺陷风险。

在 GTA 焊接中使用惰性保护气体的主要好处之一是能够产生干净、高质量的焊缝。通过消除氧气和氮气的存在,与污染相关的缺陷(如孔隙率、过多飞溅和脆性焊缝)的风险显著降低。这确保了焊接接头具有所需的机械性能,包括强度、延展性和耐腐蚀性。在航空航天和汽车等安全性和可靠性至关重要的行业中,这些品质至关重要。

Protecting the Tungsten Electrode

The non-consumable tungsten electrode is intended to initiate and sustain the arc rather than to contribute filler material (or: rather than to be consumed) during the welding process.The tungsten will react with air when it reaches temperatures above approximately 500℃—which it does during the welding process—so a shielding gas is necessary to isolate the hot electrode from the surrounding atmosphere.

Influencing Arc Characteristics and Weld Penetration

Furthermore, the use of an inert shielding gas allows for better control over the welding process. Welders can manipulate the weld pool and electrode more effectively, resulting in precise and aesthetically pleasing welds.

The shielding gas acts as the medium for arc heat transfer, and its thermal properties can be utilized to achieve deep penetration. For example, helium’s thermal conductivity is about 10 times higher than that of argon. Such high thermal conductivity allows the heat generated by the arc to be transferred to the workpiece more efficiently and uniformly.

Furthermore, due to helium’s high ionization potential, the arc requires a higher voltage, which results in a higher total arc energy. This, coupled with the arc’s diffuse, full, and broad shape (morphology), allows for increased travel speed and deeper penetration.

How to Choose TIG Shielding Gas?

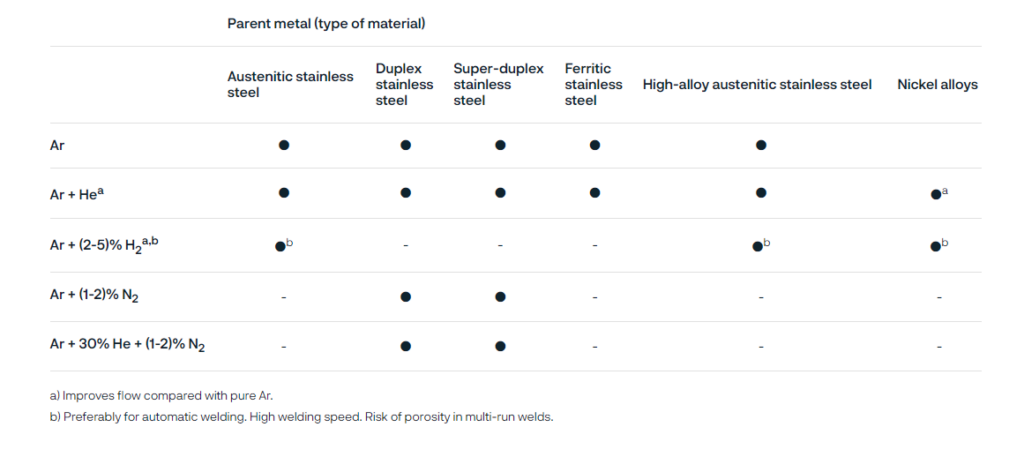

When selecting shielding gases for GTA welding, argon is the most widely used due to its versatility and protective properties. For optimal results, a purity level of 99.95%-99.99% or higher is recommended to maintain consistent weld quality and reduce contamination risks.Helium is another popular choice, renowned for its high thermal conductivity, making it ideal for applications that require deep penetration and high welding speeds. However, helium’s higher cost often necessitates the use of argon-helium mixtures, typically containing 25%, 50%, 75%, or 90% helium to balance performance and affordability. Hydrogen, while beneficial for its reducing properties that help clean surface oxides, is a double-edged sword. Its high reactivity can lead to defects such as porosity or cracking when interacting with the molten pool and electrode. To mitigate these risks, hydrogen is usually combined with argon or helium, and its concentration is kept below 5%. By carefully selecting and mixing these gases, welders can achieve optimal weld quality and performance in various GTA welding applications.

Shielding gases for TIG welding

Source:https://www.alleima.com/en/technical-center/shielding-the-weld/

客户关注的另一个方面是气体流量。控制流量至关重要,因为它会影响保护气体的稳定性和有效性。流量不足会导致气体湍流,造成污染和保护不均匀。另一方面,流量过大会浪费气体并产生不必要的成本。找到正确的平衡至关重要,现代焊接设备通常包括流量调节器,以帮助焊工保持最佳流量。

当我们探索惰性保护气体在 GTA 焊接中的用途和意义时,我们开始意识到其更广泛的含义。除了在创造保护气氛方面的技术作用外,它还象征着焊接行业注重细节、精度和安全的重要性。每个焊工都认识到,即使是最微小的污染也可能造成灾难性的后果。这种理解在焊接过程中灌输了一种责任感和一丝不苟,确保每个接头都以最大的谨慎执行。

结论

总之,惰性保护气体在 GTA 焊接中的作用是在高温焊接过程中保护焊接区域免受大气污染。这种保护气体可防止缺陷和污染,从而实现清洁、高质量的焊接。通过提供更好的控制和增强焊接稳定性,保护气体可改善整体焊接体验,从而提高生产率并降低成本。客户在购买用于 GTA 焊接的保护气体时,应优先考虑气体纯度、流速和特定气体特性等因素。最终,使用惰性保护气体反映了焊接行业的细致和精确。那么,为什么 GTA 焊接需要惰性保护气体呢?因为它可以确保焊接接头的强度、完整性和可靠性,使其能够承受最苛刻的应用。