Have you ever considered the distance the welding wire extends from your MIG gun? Do you get confused by the terms electrode extension, stick-out, and contact-tip-to-work distance? These three terms are often used interchangeably, but they each describe a different aspect of the same phenomenon. Understanding them is key to producing high-quality welds.

If you’ve experienced issues like cold welds, lack of fusion, or porosity, a common culprit could be an incorrect setting for this crucial distance. Getting this right is a simple but powerful way to improve your results. This article will explain the differences between these terms and show you how to set them correctly for a better weld every time.

目录

切换Welding Terms Explained

The terms electrode extension, stick-out, and contact-tip-to-work distance all refer to the distance from a component of the welding gun (the nozzle or contact tip) to the point where the electrode wire melts and the arc is established. In MIG welding, the wire serves a dual purpose: it’s not only the filler metal but also an electrical conductor. The length of this conductor significantly impacts the electrical resistance and, consequently, the welding current.

Stick-out

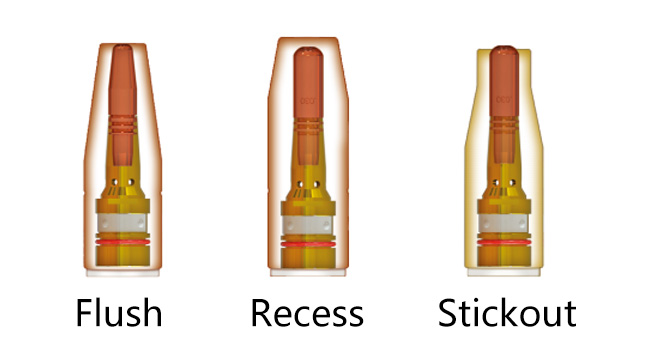

The term “stick-out” is officially defined by the American Welding Society (AWS) in their AWS A3.0 Terms and Definitions.In the context of GMAW (Gas Metal Arc Welding) and FCAW (Flux-Cored Arc Welding), stick-out is defined as: The length of the unmelted electrode extending beyond the end of the gas nozzle.

When you use a “flush” type nozzle, where the contact tip is level with the end of the nozzle, the terms “electrode extension” and “stick-out” can be used interchangeably. In this specific configuration, the length of the unmelted electrode is the same whether measured from the contact tip or the end of the nozzle.

Electrode Extension

Electrode extension is also an official term defined in AWS A3.0. It is the length of the unmelted electrode extending beyond the end of the contact tip.

Contact Tip to Work Distance

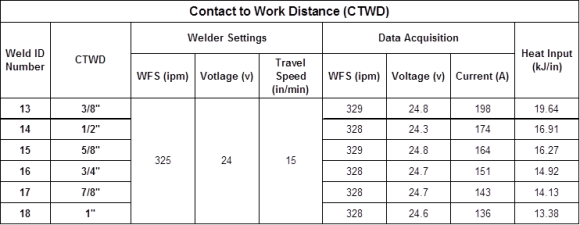

While not an official term in the AWS A3.0, Contact Tip to Work Distance (CTWD) is a crucial concept for troubleshooting and refining your welding procedures. It’s the total distance from the end of the contact tip to the workpiece, and it’s defined by a simple equation: CTWD=Electrode Extension+Arc Length. Adjusting the CTWD allows a welder to independently manipulate the welding current from the wire feed speed (WFS).

The Effect of CTWD on Welding Current

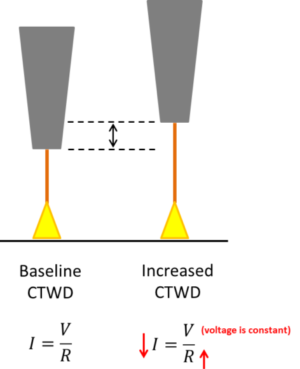

When you use a constant voltage (CV) power supply, the voltage (V) in Ohm’s Law (V=IR) remains constant. Consider a baseline CTWD, as shown in the diagram. If you increase the CTWD, the electrode extension will also increase, because the CV power supply will automatically maintain a consistent arc length.

This increase in electrode extension length directly increases the electrical resistance of the wire. According to Ohm’s Law, with a constant voltage, current and resistance are inversely proportional. Therefore, an increase in resistance will result in a decrease in welding current, leading to a colder weld with less penetration.

How CTWD Affects Current and Heat Input

Contact Tip Setback

Contact tip setback is a critical term that describes the relative position of the contact tip inside the nozzle. It refers to how far the contact tip is recessed (set back) from the end of the gas nozzle.

结论

Beyond contact tip setback—the other terms are all used to describe the crucial distances from the welding gun to the workpiece. Mastering these concepts gives you direct control over your weld’s heat, penetration, and quality.

A minimum stick-out is beneficial because it preheats the wire in a short amount of time. This preheating can help vaporize any moisture in the wire’s core, preparing it for a smooth transfer to a molten state as it enters the arc. However, an excessive stick-out is a major concern as it can create a lack of shielding gas coverage over the weld zone, leading to defects like porosity.