When it comes to semiautomatic welding processes, GMAW (Gas Metal Arc Welding) and FCAW (Flux-Cored Arc Welding) are two popular methods that professionals often find themselves choosing between. Understanding their differences and advantages helps determine the right process for your project. This article will cover key considerations, highlighting the specific benefits and suitable applications for each method.

目录

切换What Is Semiautomatic Welding?

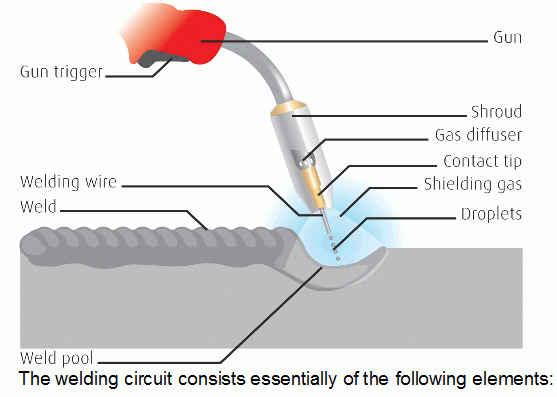

Before we get started,let’s first clarify what semiautomatic welding means.Semiautomatic welding means the welding equipment feeds the welding wire automatically, while the welder manually controls the movement and positioning of the welding torch. This combination provides both flexibility and consistency, making it widely used across various industries.

Advantages of GMAW:

首先,让我们深入了解一下 GMAW 的具体内容。气体金属电弧焊,也称为金属惰性气体 (MIG) 焊接,利用实心焊丝和保护气体混合物来产生电弧。这种焊接工艺具有许多优点,例如焊接速度快、焊接质量好,并且能够焊接各种材料,包括铝、不锈钢和低碳钢。GMAW 通常用于汽车工业、造船业和一般制造业。

Advantages of FCAW:

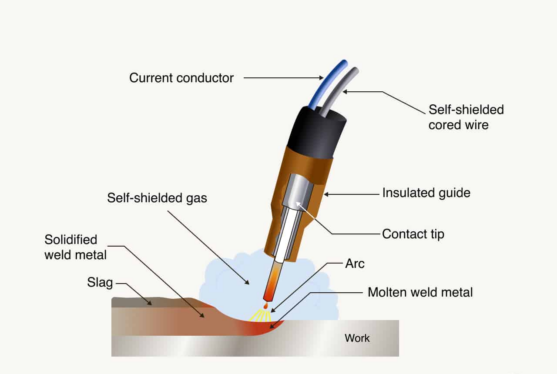

另一方面,我们有药芯焊丝电弧焊 (FCAW),它采用填充焊剂的管状焊丝电极。这种焊剂具有多种功能,包括提供针对大气污染的保护、减少对保护气的需求以及增强焊缝的机械性能。FCAW 特别适合户外焊接,因为它可以在多风或肮脏的条件下有效操作。此外,与 GMAW 相比,FCAW 具有更高的熔敷率,这意味着它可以实现更快的焊接速度。这使得该工艺适用于大规模工业应用,例如结构钢制造、管道焊接和重型设备制造。

Source:https://weldguru.com/

Comparison Between GMAW and FCAW:

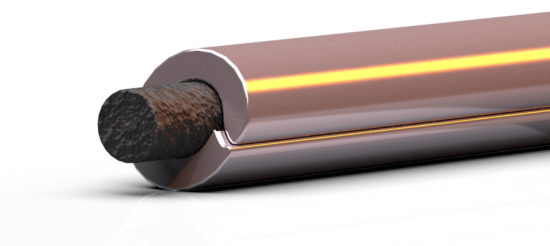

GMAW and FCAW utilize almost identical welding equipment, including welding torches, helmets, and welding machines. The primary difference lies in the electrode type: GMAW uses solid wire and relies on shielding gas stored in cylinders, while FCAW employs flux-cored wire.

This difference in wire type also dictates the welding drive rolls used: GMAW typically employs V-groove rolls for solid wire, while FCAW generally requires V-knurled rolls for flux-cored wire. Learn more about choosing the right welding drive rolls here.

A notable advantage of FCAW is that certain flux-cored wires are self-shielded and do not require external shielding gas (also called FCAW-S). This makes FCAW particularly advantageous for outdoor welding, as it eliminates the need for additional gas cylinders, reducing equipment complexity and lowering gas expenses.

When choosing between GMAW and FCAW, customers carefully consider the benefits of each process. GMAW offers versatility in welding various materials, including aluminum, stainless steel, and mild steel, with minimal adjustments. This flexibility is ideal for industries like automotive manufacturing, where different metals frequently appear on the same production line.

Flux-Core Source:http://weldnotes.com/?p=123

Meanwhile, FCAW is favored by customers needing higher deposition rates, deeper penetration, and the convenience of outdoor applications. By using self-shielded flux-cored wires, FCAW simplifies equipment requirements, reducing overall costs and enhancing portability, particularly in environments where external shielding gas would be challenging or impractical to manage.

However, FCAW generally produces more spatter compared to GMAW and requires additional time for cleaning slag after welding. Users should account for this extra step when choosing FCAW for their applications.

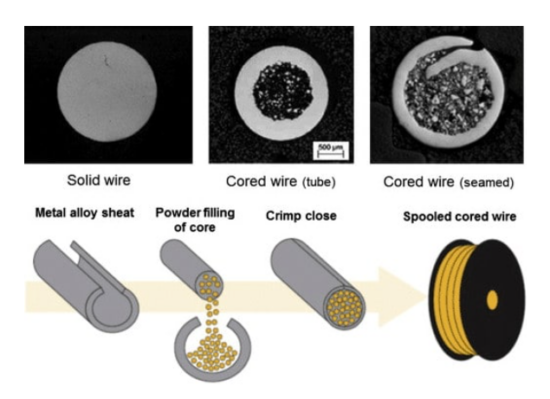

How to Identify Flux-Cored and Solid Wires?

To quickly identify flux-cored and solid wires, try bending the wire. Solid wire is relatively flexible and can usually be bent more than 90° multiple times without breaking. Flux-cored wire, however, typically breaks after just one or two bends. Additionally, some lower-quality flux-cored wires can be unwound by twisting the wire ends with two pairs of pliers—better-quality flux-cored wires will not easily come apart. It’s also important to note that flux-cored wires left exposed to moisture for extended periods may absorb moisture into the flux, causing potential welding issues.

Source:https://materialwelding.com/metal-cored-welding-vs-flux-cored/

Different Applications:

除了具体的优势之外,应用领域也对客户的决策过程产生了很大的影响。在汽车行业,减重和省油是重中之重,而 GMAW 在其中发挥着至关重要的作用。由于 GMAW 能够焊接铝等轻质材料,因此在现代汽车车身的生产中,它经常用于连接铝板。此外,在造船业中,不锈钢的耐腐蚀性也备受推崇。GMAW 适用于焊接不锈钢,因此造船厂可以制造出可靠、耐用且耐腐蚀的结构。

对于涉及大型结构的行业,例如建筑或制造,FCAW 成为首选。FCAW 的快速焊接速度和高沉积率使其成为处理重型应用的理想选择。以建造桥梁为例。提供支撑的钢梁的制造需要高效且牢固的焊接。通过使用 FCAW,焊接过程将加快,从而提高生产率并缩短施工时间。

结论:

总之,了解 GMAW 和 FCAW 之间的差异对于选择最合适的半自动焊接工艺至关重要。GMAW 在焊接各种材料方面的多功能性使其成为汽车等使用多种金属的行业的理想选择,而 FCAW 能够提供更高的沉积速率和更快的焊接速度,这对于管道焊接和大型结构等重型应用非常有益。通过考虑符合其特定需求的产品优势和应用领域,客户可以做出明智的决定,确保其焊接项目取得有效的结果。

请记住,无论您选择 GMAW 还是 FCAW,这两种工艺都有各自的优势和专业领域。最终还是要了解您的项目要求、您将使用的材料,并将这些因素与每种工艺提供的优势相结合。因此,在为您的半自动焊接项目选择 GMAW 还是 FCAW 时,请做出明智的选择。

FAQs: Can you run flux core wire in a MIG welder?

Yes. You will need to make a few changes to your machine, including:

- Changing the polarity. For self-shielded wire (FCAW-S), you must reverse the polarity so the gun is negative and the work clamp is positive.

- Switching the drive rolls. Use knurled V- or U-groove drive rolls.

- Not using shielding gas. The flux inside the wire creates its own gas shield.

- Using a drag (pull) technique instead of a push technique.