目录

切换Spool Gun vs. MIG Gun: Key Differences

When discussing welding aluminum, the spool gun invariably comes up. Yes, it’s a specialized tool built upon the foundation of a standard MIG gun, yet its unique design offers distinct advantages for specific applications. So, what sets them apart in operation, what makes the spool gun ideal for welding aluminum, and what should you consider when choosing a spool gun model? Let’s explore the core differences.

Unique Feeding Mechanism

The primary difference between these two tools lies in their unique wire feeding mechanisms, which directly dictates their operational strengths.

With a standard MIG gun, the welding wire travels a considerable distance: from the wire feeder (located in or near the welding machine), through a guide tube (liner) inside the welding cable, and finally to the gun’s contact tip. While the feeder and gun ends are fixed, the cable length can vary based on need. However, an overly long guide tube significantly increases wire feeding resistance. This can lead to issues like difficult arc starting, poor performance with softer wires, and increased fatigue due to added gun weight as the cable gets heavier.

A spool gun, on the other hand, solves these challenges by having a small wire spool (typically 1lb or 2lb) mounted directly on the gun itself. It also features its own integrated drive rollers. This design drastically shortens the wire’s travel path, making it perfectly suited for soft, easily deformable wires like aluminum, which would otherwise “bird-nest” or kink in a traditional setup. This short, direct path also removes the length limitations of standard MIG guns, allowing for astonishing reaches, often up to 12 meters (40 feet) or more, making spool guns ideal for long-distance or remote welding tasks.

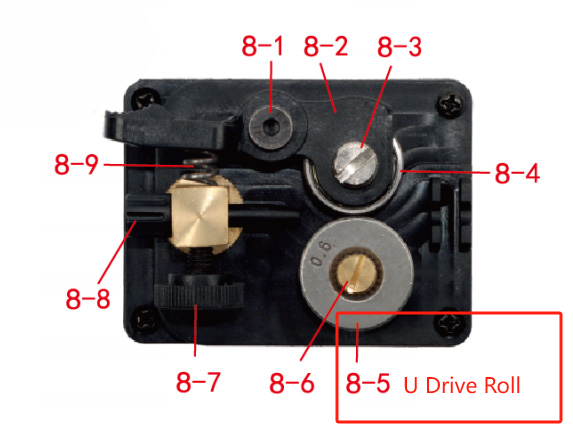

Drive Rolls & Wire Compatibility

For spool guns, U-groove drive rolls are the default choice, designed specifically to gently handle and feed soft aluminum wire without deforming it. However, the U-groove is not the only option available. Just like standard MIG guns, spool guns can also be fitted with different drive roll types, including V-groove (for harder, solid wires like steel and stainless steel) and knurled (for flux-cored wires). If you intend to weld materials other than aluminum with a spool gun, you’ll need to replace the drive rolls with the appropriate type and potentially change the liner to ensure smooth feeding.

For a detailed understanding of the different drive roll types (U, V, and knurled) and their specific applications, you can learn more here.

Portability & Reach

The integrated spool and motor make a spool gun heavier and bulkier than a standard MIG gun. This large size can make it difficult to use in tight or restricted spaces. Additionally, the small onboard spools require frequent wire changes, interrupting workflow on larger projects. Spool guns also typically have a lower duty cycle, ranging from 30% to 60%.

Conversely, a standard MIG gun is lighter and more ergonomic. Its greatest advantage is the diverse range of options, including various handles and a wide selection of auxiliary accessories. This variety allows a welder to customize their setup for a more comfortable experience. Furthermore, standard MIG guns can be paired with water-cooled systems to achieve a 100% duty cycle, which is essential for continuous welding without overheating.

Polarity Selection: AC or DC

MIG welding, whether with a standard gun or a spool gun, primarily uses DC (Direct Current). Specifically, it uses DC Electrode Positive (DCEP) for most common applications (steel, stainless steel, aluminum). While some specialized AC TIG machines exist for aluminum, MIG welding for aluminum (with a spool gun or push-pull gun) is always DC.

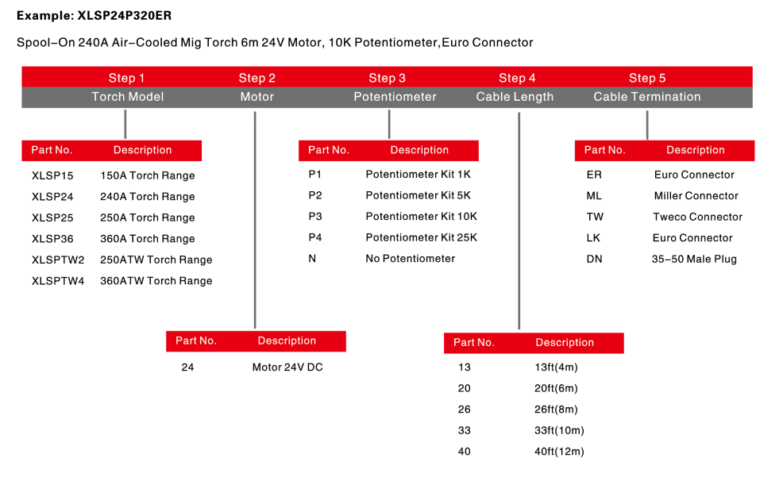

How to Choose a Spool Gun

Before making a purchase, you should confirm key specifications such as the Torch Model, Motor, Potentiometer, Cable Length, and Cable Termination to ensure compatibility with your welding machine and your specific needs.